A few years ago, I bought a Chinese manufactured Vertical Axis Wind Turbine from a vendor in Canada. After it travelled the world, and was delivered at my doorstep, it seemed it had fallen down or been thrown about a couple of times. Anyway, a bit naive, I then thought it would still work well after I revised and mended the “most bent” things. Of course, the swept area of the VAWT was way to small to produce any useful electrical power. And the disc generator turbine had too much resistance when some weight was put on it. Probably the result of the bad handling during transport. Disappointed with its performance, I disassembled it, and then placed it on a shelve where it remained for a few years.

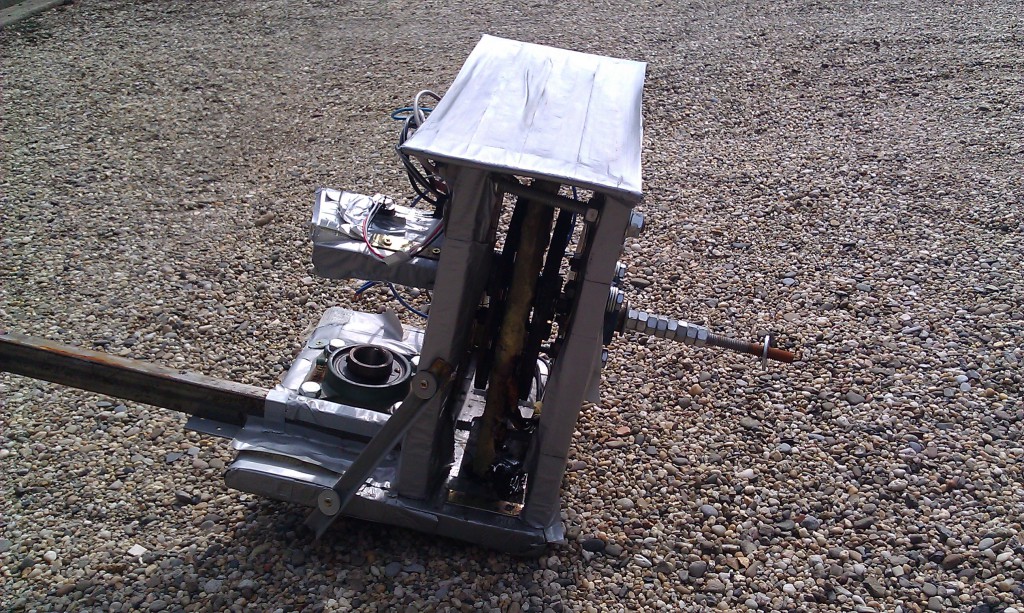

During that period, I built quite a few axial flux generator wind turbines to tryout different aspects and learn about them. They were built with cheap materials such as wooden OSB boards, because they were not meant to last more than one or maybe two seasons. A couple of weeks ago, I decided it was time to replace the test horizontal wind mill in the back yard, and maybe use it as a wind turbine simulator. One gets used to have something spinning in the backyard, so I decided to replace it. The Vertical Axis Wind Turbine was converted into a Horizontal Axis Wind Turbine: Just a matter of attaching blades to it, and placing it on a hard (exotic) wooden plank, and adding a tail on the design. But maybe that sounds simpler than it was. Anyway, in its second life, it works a lot better. On the picture, one can see the disc generator and the attached blades:

We can now take a closer look at the removed axial flux wind turbine. It is an axle-through-two-ball-bearings design and resembles a bit a bird house. One can see the two discs with magnets, and the small flat three-phase wound stator in between. There are three coils per phase, so nine coils in total. Small triangular coils with about 90 turns of wire. The phases are connected in a star configuration. Aggregated resistance across one phase is a bit too high at 1.5 Ohm. There is quite a distance gap between the small (200mm diameter) magnet discs (which have 12 poles) and the stator, but it will reach 14V at about 250 RPM. Not the most efficient generator tryout I made, but it works and will peak at about 200W. It is matched with 1200mm diameter blades.

There are some problems with it, and things I would do differently now:

- There is a bit too much mechanical resistance, so better bearings with lower rotational resistance should be selected.

- The stator is not flat enough, hence the magnet discs distance is more than it should be.

- 90 turns of wire is too much, it adds unwanted resistance and the voltage increase is not worth it. 75-80 turns would be better.

- A 12mm full threaded bar was used, where a full 12mm rod with limited threading was probably better.

- It is better to use a hard UV resistant plastic instead of OSB board.

- Many other things…

Speak Your Mind